-

Client

Magnox South Sites

-

Business need

Ensure that a fire suppression system performed as it was designed, as part of a nuclear safety case.

-

Why Frazer-Nash?

Our expertise in the nuclear sector includes a strong emphasis on computer modelling for thermal and fluid analysis

The challenge

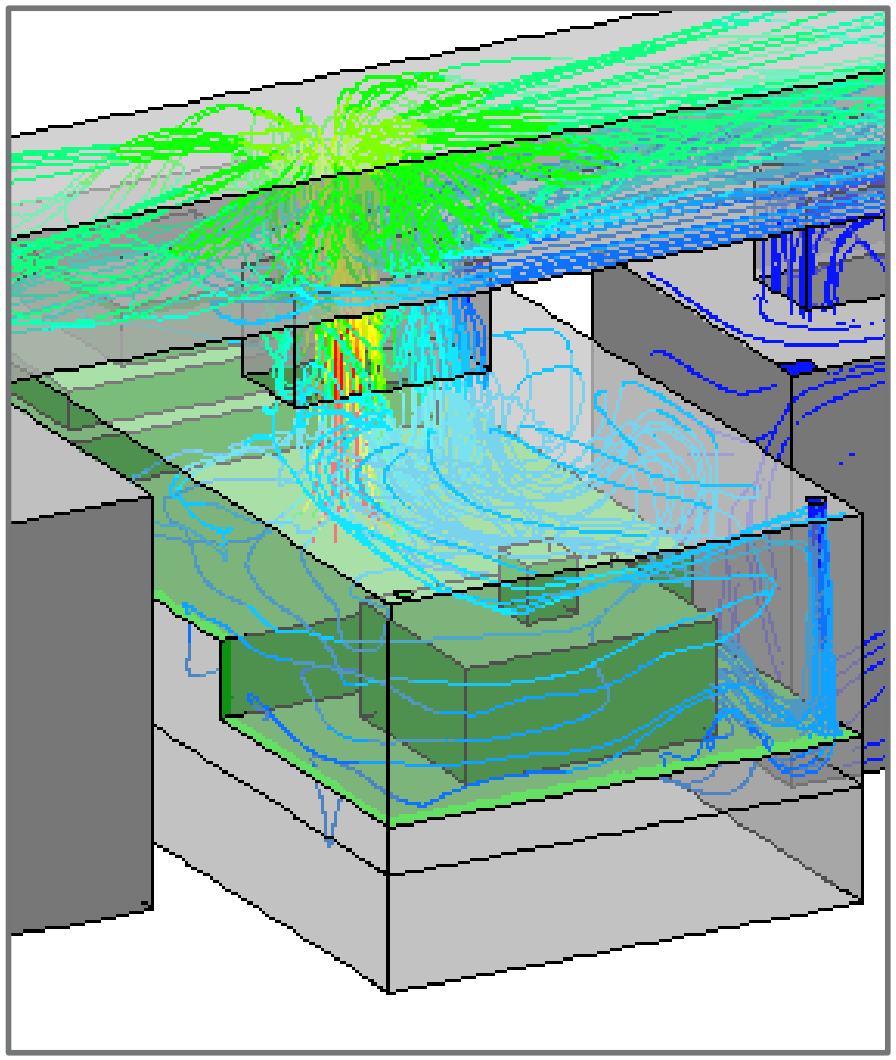

Although our client had a thorough safety case for the storage of Magnox Fuel Element Debris in the Waste Vaults of Berkeley Power Station, this policy did not cover the retrieval of the waste from the vaults. A major concern was the fire suppression system, as much of the waste consists of a mixture of graphite and magnesium - both of which are flammable.

In the event of a fire, this system injects Argon into the vault, thereby starving it of oxygen. Under storage conditions, the vault covers are closed and the argon is used to displace the air in the vault due to its greater density. However, under retrieval conditions the vault covers could be open, and the thermal plume from a fire could carry some of the Argon out of the vault and into the retrieval tunnel, allowing additional air to enter the vault and feed the fire. Frazer-Nash were commissioned to assess the effectiveness of the Argon fire suppression system to take this into account as part of the client’s safety case.