-

Client

Various

-

Business need

To verify the safety and conformance to regulations of gas turbine enclosures on offshore platforms.

-

Why Frazer-Nash?

Frazer-Nash was one of the lead developers for CFD for ATEX and has already helped many offshore operators demonstrate compliance.

The challenge

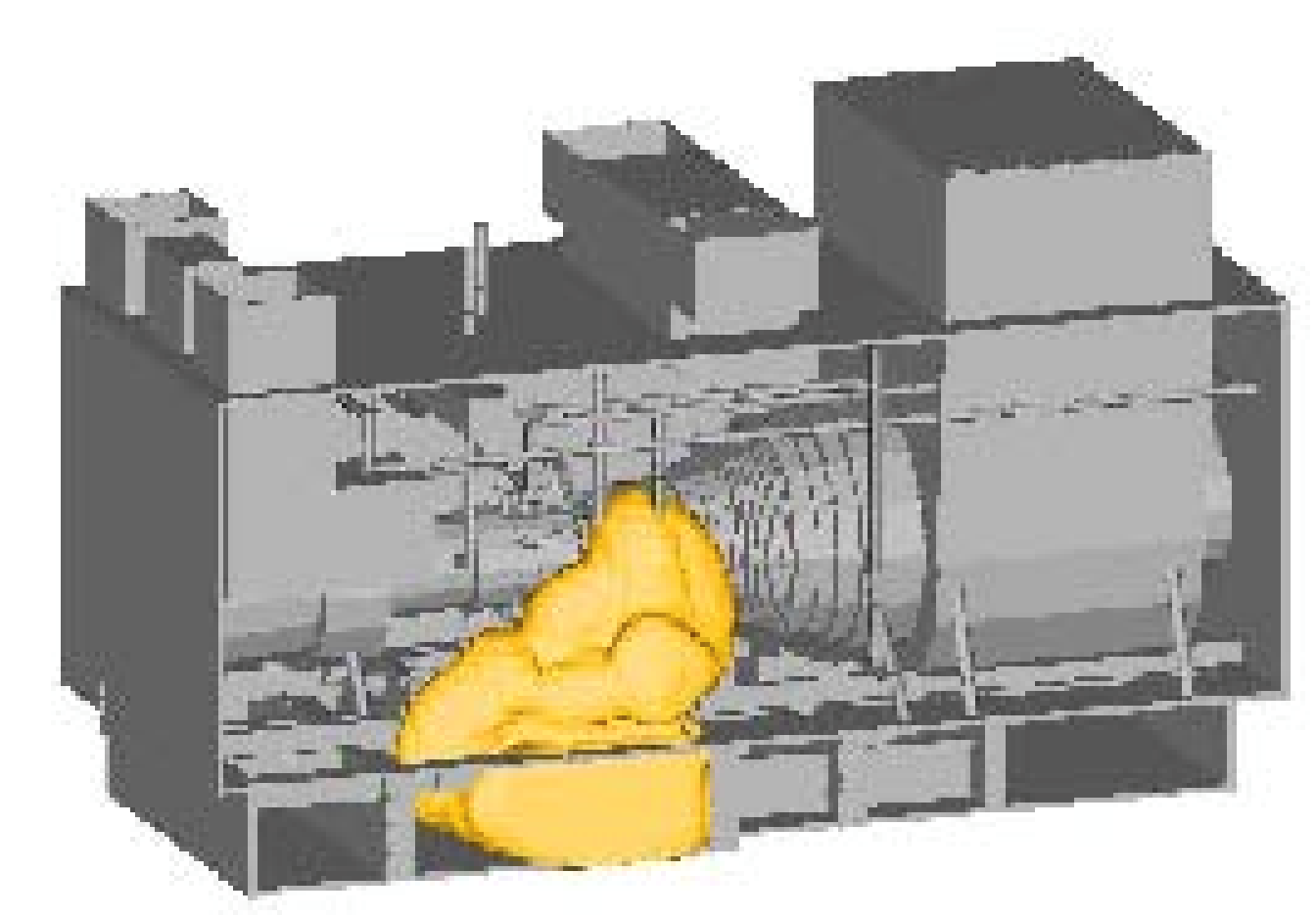

The considerable power demands of offshore production and processing platforms are usually met by the use of gas turbine power generators that provide reliable and cheap energy. However, these units are encased within acoustic enclosures which create the risk of explosion as the hot surfaces and natural gas combine.

The design of these enclosures is governed by the pan-European DSEAR and ATEX Regulations which require assurances that the largest undetectable gas leak will not lead to an uncontained explosion.

Our solution

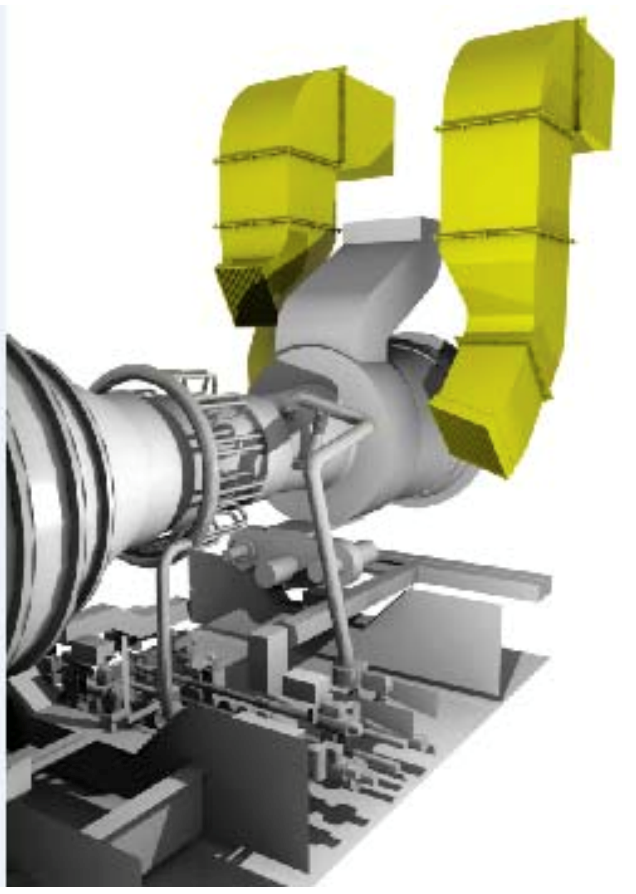

Frazer-Nash worked under a joint industry project with the Health & Safety Executive to develop a process that would provide this assurance. Using a mathematical modelling technique called Computational Fluid Dynamics (CFD), we analysed how the turbine and its enclosure were constructed.