-

Client

Confidential

-

Business need

Our client requested a design and supporting calculations for a modular steel blast resistant building for a petrochemical site.

-

Why Frazer-Nash?

We have extensive experience of blast resistant design and a track record of working with the client.

The challenge

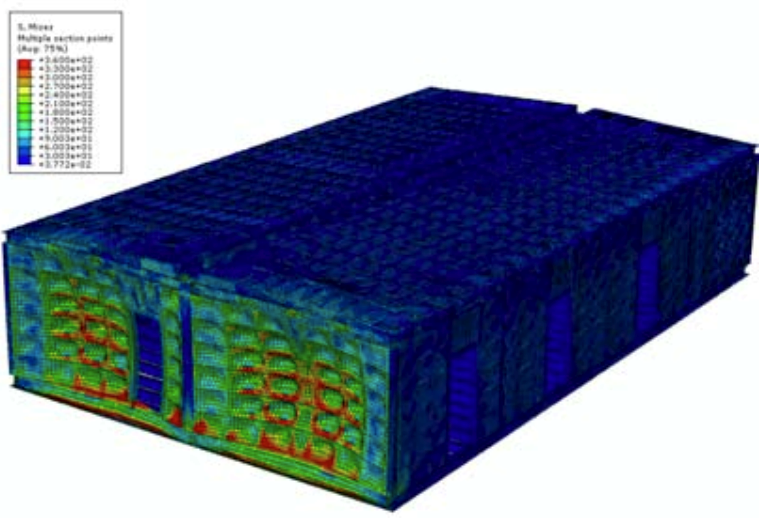

Control buildings and other critical structures on oil refinery sites must be blast resistant to ensure that people and critical equipment are protected. Our client builds the fully fitted out blast resistant modules, including control buildings and substations, in parts to be shipped to site.

There are often requirements for large open spans, which means that the roof structure and connections are particularly critical. Our skills and experience mean we can produce a building which meets all the strength requirements but is as light as possible and easy to construct, enabling our client to win projects in a competitive market place.

Our involvement

Initially we carried out scoping calculations on the building which enabled our client to enter a competitive bid and win the work. We were then awarded the contract to carry out the outline design and supporting blast and code assessments for the building.