-

Client

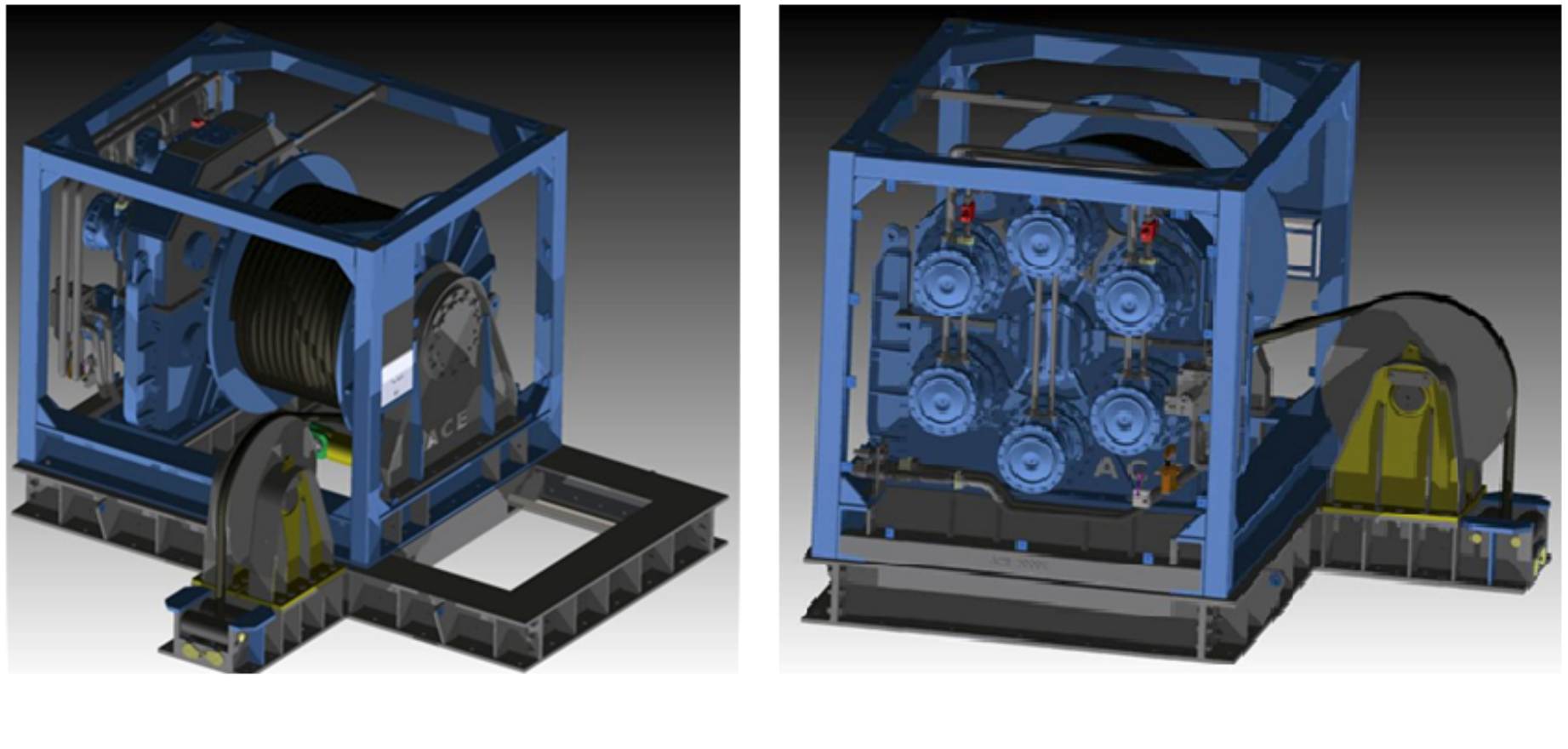

ACE Winches Limited

-

Business need

To carry out a Failure, Modes, Effects and Criticality Analysis (FMECA) on Winches to be fitted on a North Sea oil platform.

-

Why Frazer-Nash?

We provide advanced and independent engineering analysis and design services to the petroleum, nuclear, rail and defence industries.

The challenge

ACE Winches are supplying two hydraulically powered, heavy capacity winches to a Danish oil and gas company as part of a repair scheme requiring various lifting arrangements at different stages of the programme.

Due to the inherent risks associated with the particular platform, additional design integrity assurance was required in the form of a Failure Mode Effects Analysis and Criticality Analysis (FMECA). The identified failure modes needed to be assessed in terms of severity and probability, what mitigation is in place, and also if any further risk reduction activities were required.

Our involvement

The purpose of this FMECA Study was to identify potential design weaknesses through a systematic analysis of the modes of failure, their causes and effects. The FMECA included analysis of failure mode criticality in terms of severity and probability, which enabled the failure modes to be ranked in terms of criticality (risk).