-

Client

Major oil and gas operator

-

Business need

To assure the fitness for service of the pipework for current and future operation.

-

Why Frazer-Nash?

Frazer-Nash has extensive experience in code based assessment, recognising its intent and extending assessment to simulation based analysis.

The challenge

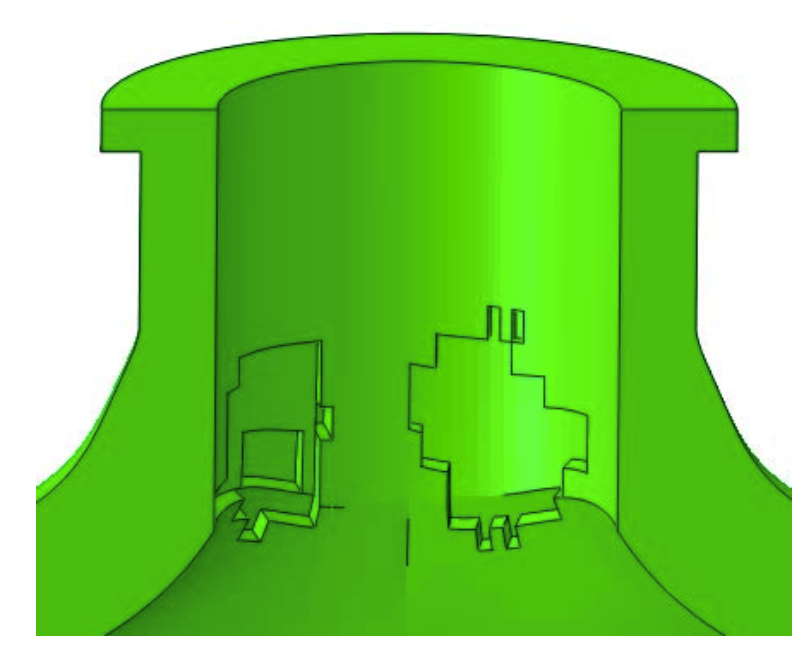

During routine maintenance, damage was found to have occurred to the inner bore surface of a branch connection in a Water Injection Header.

Our client identified between 20 and 30 similar connections on the same header which could have suffered similar damage. This was an unexpected problem and only a very short period of time was available to inspect the branches and substantiate their integrity before production would be affected. The branch connections were quickly identified to be a bespoke design and no detailed drawings were available.

Our solution

We developed a simple, flexible and effective approach to quickly identify those branch connections that had suffered damage attributed to a combination of corrosion and erosion damage. Our structural analysis team identified the key dimensions and the necessary inspection grid for Non-Destructive Testing (NDT) thickness measurement.