-

Client

Various

-

Business need

Demonstrating the safe operation of an offshore asset, requires quantifying the risk associated with fire, smoke, hydrocarbon gas and hot plume dispersion for a given design.

-

Why Frazer-Nash?

Frazer-Nash has extensive experience in dispersion modelling on offshore assets. We are members of HSE steering groups into gas dispersion modelling and understand all aspects that are required for a suitable design.

The challenge

The orientation and layout of equipment can profoundly influence the operability and safety of an offshore platform. Ensuring safe operation is paramount and quantifying risks at the design phase is a key step in achieving this.

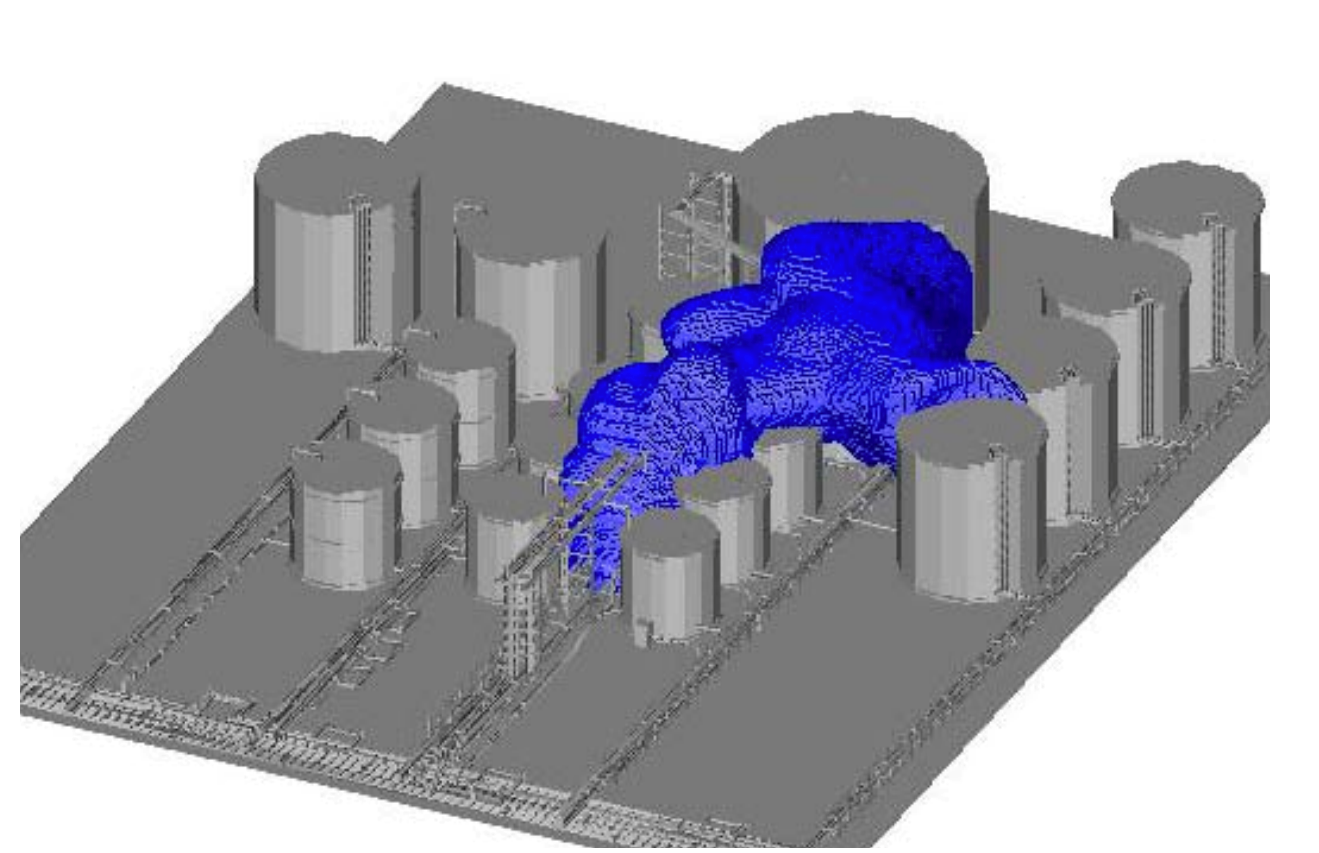

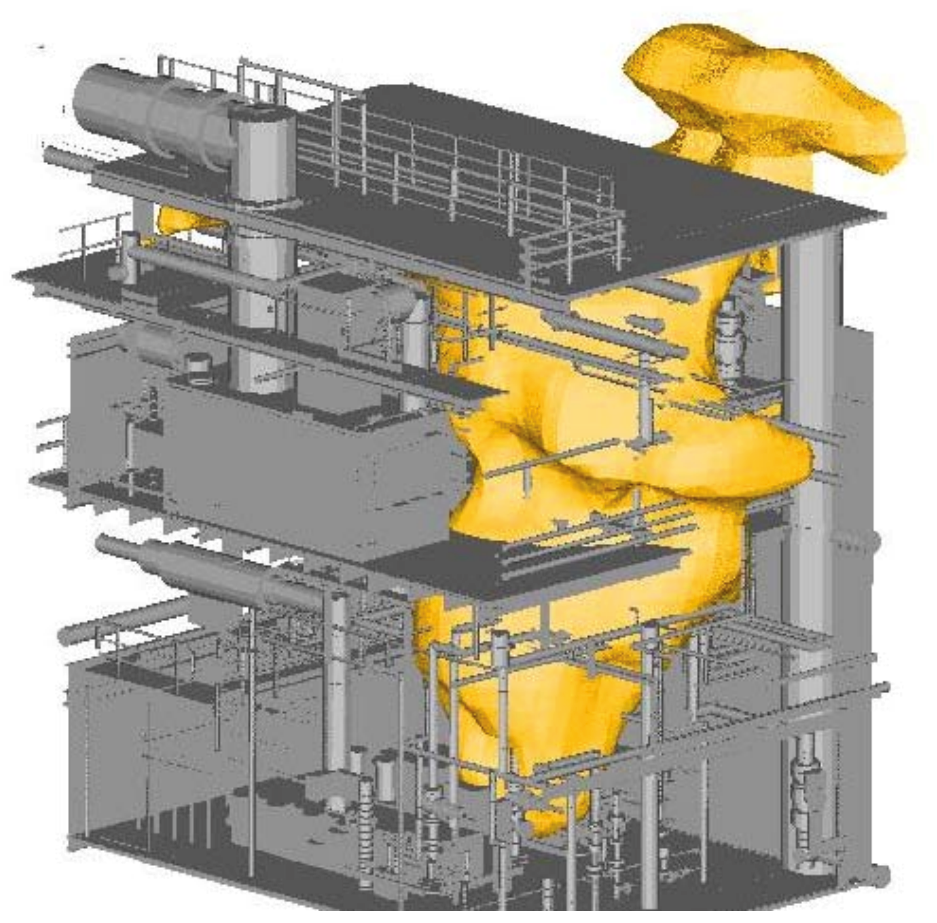

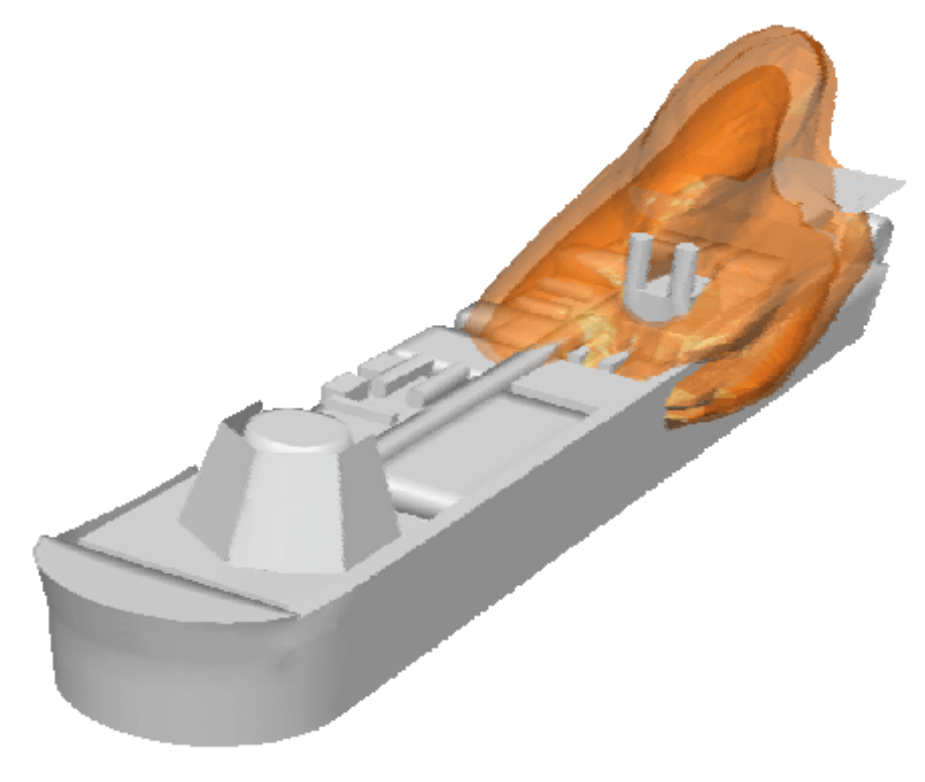

Dispersion modelling is a means of quantifying the interaction of concentrated sources with prevailing winds around an asset. The wind acts to dilute and disperse smoke, gas and hot exhaust plumes which can either increase safety or drastically diminish it.

The challenge lies in designing assets that utilise wind dispersion to increase safe operation. To this end, we perform dispersion modelling to aid safe helicopter and cranes operation around hot gas turbine exhaust plumes, detection of hydrocarbon leaks prior to ignition and design of safe escape routes and secure refuges in the event of fire.

Our involvement

We perform both near and far-field dispersion predictions to evaluate the safe operation of asset designs using Quantitative Risk Assessments (QRA) and safety cases.

Building on our knowledge of far-field Atmospheric Dispersion Modelling (ADM) techniques that account for meteorological conditions and thermal properties of plumes we use Computational Fluid Dynamics (CFD) to predict dispersion around congested offshore assets.